How do I choose the right block or pulley?

How do I choose the right block or pulley?

There are many different blocks and pulleys out there, but how do you know which is the right one? There are so many options that it’s hard to make the right choice. You want both the right block and value for money. This can quickly become expensive and it would be unfortunate is the block of your choice turns out to be the wrong one. In this blog we will discuss this in more detail.

Different materials of blocks

The most obvious difference between blocks are the material and bearing that is used. Regarding the material, it is generally quite straightforward. The stronger the block has to be, the stronger the material of the block needs to be. Composite (reinforced plastic) is often used for the standard range. If a block needs to be stronger, aluminium or a combination of both will be used. For super yachts and high-end racing yachts, you also see blocks made of titanium and/or carbon. For most sailing vessels these will not be common.

A block should be selected based on the strength it needs to carry. This will automatically determine the material the block is made of. Most brands offer you an overview of the best choice for the load. So what should you pay attention to?

Type of application

Before you can choose a block correctly, it is important to know what the block will be used for. There are two types of application:

Dynamic application

In a dynamic application, the sheaves of the block must be able to rotate properly under high load. For example, a mainsheet where the sheaves have to rotate regularly whilst under load.

Static application

A block is statically loaded when the sheave remains still, under load, for a longer period of time. Mastbase blocks for halyards are a good example. After hoisting, which causes relatively little load, the blocks stand still and are only loaded when sailing.

Type of bearings

The most important difference between blocks is the type of bearing. Now that we know what kind of applications there are, it is important to look at what kind of bearing fits the application.

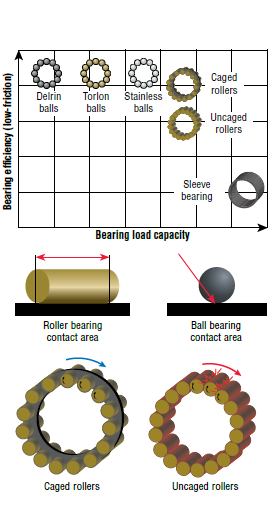

The properties of bearings are determined by a combination of contact surface, material, the distance between the bearings and whether a bearing rolls or slides.

Type of bearings

- Ball bearings: very low friction, medium-load capacity

- Roller bearings: low friction, high-load capacity

- Plain bearings: high friction, high-load capacity

Contact area

A larger contact area between bearing and sheave results in more friction, but also increases the load capacity.

Ball bearings are only loaded at a small surface. Roller bearings have a larger contact area and have more friction, but are also considerably stronger. It is important to ensure that ball/roller bearings do not collide with each other. This can cause additional resistance. A block with ball bearings should therefore never be completely full with balls. There is always one short to keep enough space. With roller bearings it is harder to keep some space. In some blocks the roller bearings are placed in a ‘cage’ or spacer. This prevents resistance between the bearings. See illustration.

Plain or bush bearings have nothing to reduce friction. Such blocks are strong and can withstand static load. The advantage is that such blocks are relatively cheap and strong.

Why is a block with ball bearings not always a ball bearing block?

Sometimes it may appear that a block/pulley is a ball bearing block, but it turns out not to be. This is confusing because the block clearly has ball bearings in the sheave. So why are they there?

With roller and plain bearing blocks you will sometimes also see ball bearings. These bearings are meant to reduce the friction between the sheave and cheeks of the block. In other words, to absorb axial force. When a block is loaded with a halyard or sheet, the sheave wants to tilt. This lateral load causes the sheave to rub against the sides of the block, causing extra resistance. This resistance can be reduced by adding ball bearings to the sheave. The ball bearings do not absorb the axial load (force of the sheet) and therefore it is not a ball bearing block.

What is the consequence of this friction in blocks?

Now we know what types of bearings including their characteristics there are, we can also take a look at what this will mean onboard your boat. What is the real loss caused by friction and what does this mean?

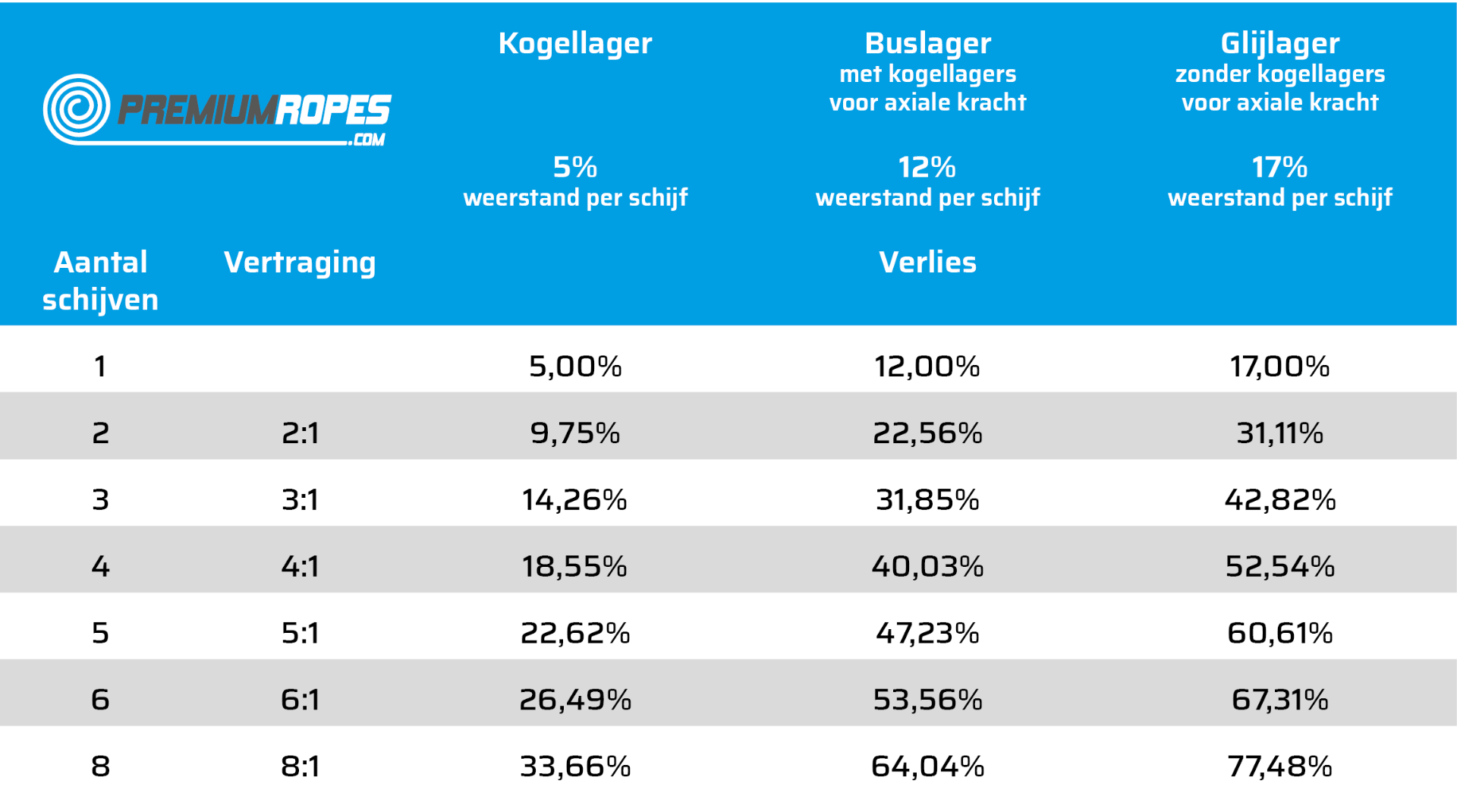

In the table we have listed the most common bearing types with the friction(%) per sheave. You can clearly see that in some cases the friction increases enormously.

For example, the 6:1 cascade. This is often used on yachts. The reduction using a plain bearing block is 67,31%. This means that two-third of the strength you put in, is wasted on resistance! If you choose the same cascade but using ball bearing block, this is a lot lower and only 26,49%. The more you cascade, the more resistance/friction you get. With a 4:1 ball bearing block system, it is easier to pull in your main sail than with a 8:1 roller bearing block system.

What can we conclude from this?

The main difference between blocks is the type of bearing and the material used. A bearing with a larger contact area is stronger, but also has more friction. Another important consideration are of course the costs. Ball bearing blocks are often more expensive than a simple block with plain bearings. Important to remember is that sometimes a 4:1 purchase using ball bearings is enough, while it requires a 8:1 purchase using roller bearings to get the job done. In terms of costs the difference might not so big anymore.

A useful guideline when choosing blocks. For dynamic applications such as a main sheet, spinnaker sheets and jib sheets, a block with ball bearings is best. For larger and/or racing boats with higher loads, roller bearings blocks are best. For static applications such as mastbase blocks, vangsystems or backstays a plain bearing block will do fine.

This information might all be a bit much, please do not hesitate to contact us for help.

Premium Ropes offers a wide range of blocks of well-known brands. Click on the links below for an overview per type of bearing.